FDM 3D printers use thermoplastic filaments, which are heated, extruded, and layered to create three-dimensional objects. Understanding the structural components of an FDM 3D printer can help users operate, maintain, and troubleshoot their machines more effectively. Here’s a breakdown of the key parts that make up an FDM 3D printer and how each contributes to the printing process.

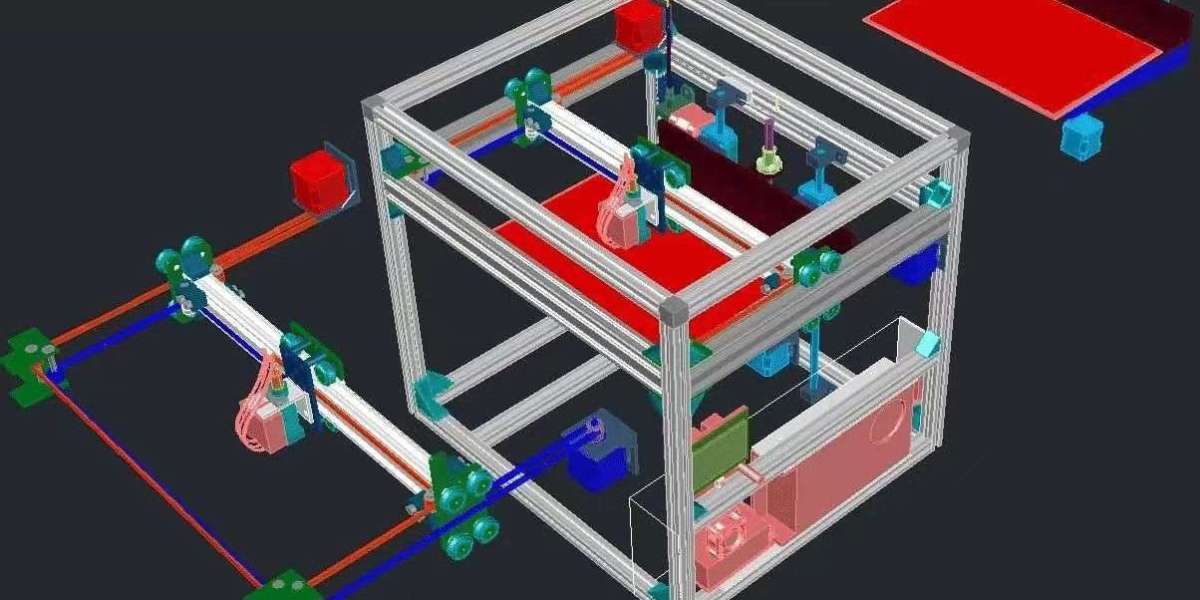

Frame and Enclosure

The frame serves as the foundational structure of the 3D printer. It supports and holds all other components, ensuring stability during printing. Frames can be made from materials like aluminum, steel, or high-quality plastic. Some FDM printers come with an enclosure that surrounds the frame, which can help maintain a stable temperature, reduce warping (especially important for materials like ABS), and improve safety by shielding moving parts.

Print Bed

The print bed, also known as the build plate, is the surface on which the filament is deposited layer by layer to create the final object. Print beds can be heated or non-heated. Heated beds are particularly useful for filaments like ABS and PETG, as they help improve adhesion and reduce warping. Many print beds have additional coatings or removable surfaces to make object removal easier once printing is complete. Beds that can auto-level are also becoming more common, simplifying the calibration process.

Extruder Assembly

The extruder assembly is responsible for feeding the filament into the hot end, where it’s melted and deposited. There are two main extruder types in FDM printers:

- Direct Drive Extruders: These extruders are attached directly to the hot end, minimizing the distance the filament needs to travel. They provide better control, especially with flexible filaments, and are popular in printers requiring high precision.

- Bowden Extruders: In Bowden setups, the extruder is separated from the hot end, feeding filament through a tube. This design reduces the weight on the print head, allowing for faster movement and less wobbling, which is beneficial for high-speed printing.

Hot End and Nozzle

The hot end is where the filament is heated to its melting point. It consists of a heating element, thermistor (to regulate temperature), and a nozzle through which the melted filament is extruded. The nozzle diameter determines the extrusion width, impacting the print’s resolution and detail. Standard nozzle sizes are 0.4 mm, but smaller or larger nozzles can be used based on printing requirements. Nozzles should be well-maintained and occasionally replaced, especially after printing with abrasive materials, as these can cause wear.

Axes and Motion System

An FDM 3D printer operates along three primary axes—X, Y, and Z—allowing for precise movement to build layers. The X and Y axes control the movement of the print head across the horizontal plane, while the Z-axis controls the vertical movement of the print bed or print head.

To facilitate these movements, FDM printers rely on various mechanical components:

- Linear Rails or Rods: Provide smooth, stable movement along each axis.

- Stepper Motors: Control each axis with high accuracy, turning incrementally to adjust positioning.

- Belts and Pulleys: In Cartesian printers, belts and pulleys control the X and Y movement, while screws control the Z-axis.

Different motion systems like Cartesian, CoreXY, and Delta have distinct advantages, influencing print speed, precision, and structural layout.

Control Board and Firmware

The control board is the brain of the 3D printer, managing all electrical functions, including motor movement, temperature regulation, and user interface. It reads the G-code, which translates the 3D model’s digital information into specific instructions for the printer. Firmware, the software embedded in the control board, handles processing and executes commands, playing a crucial role in print quality and operational efficiency.

User Interface

Most FDM printers come with a user interface (UI) to allow easy control over settings and monitoring. This interface can be a simple LCD screen or a touchscreen, giving access to essential functions like print start, stop, temperature control, and bed leveling. Some advanced FDM printers have Wi-Fi capabilities, allowing for remote monitoring and control via computers or mobile apps.

Conclusion

The structure of an FDM 3D printer is an intricate combination of components that work together to transform filament into a finished object. Each part, from the frame and print bed to the extruder and control board, plays a critical role in the success and precision of the printing process. By understanding these components, users can enhance their printing results, conduct effective maintenance, and troubleshoot issues more efficiently. Whether you’re a beginner or an experienced maker, a solid grasp of your printer’s structure is key to maximizing its potential and achieving high-quality prints.